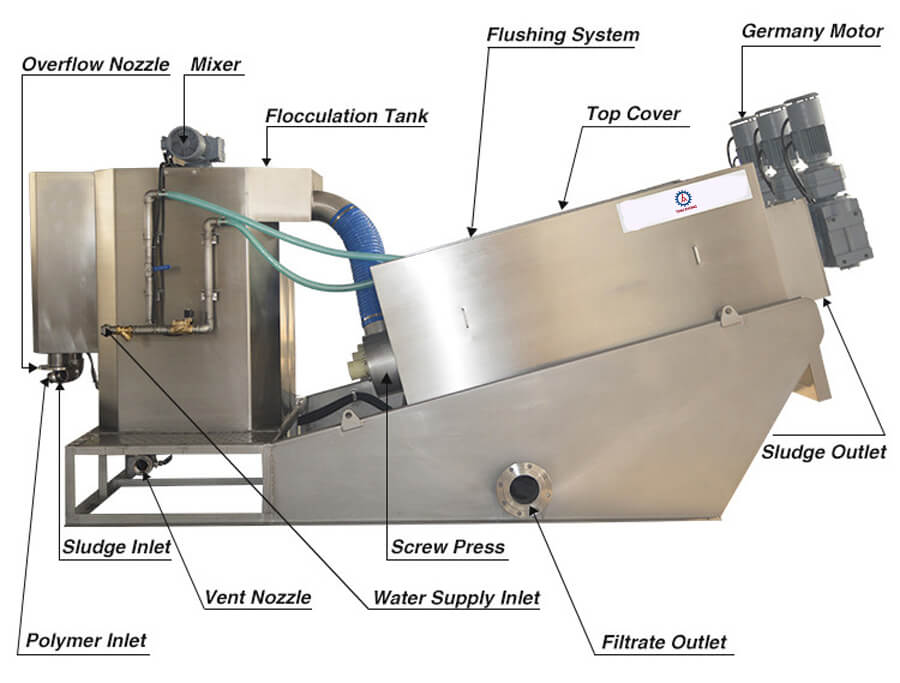

The sludge dewatering system is a device used for separating sludge and water. The equipment is mainly composed of a frame, screw shaft, moving ring, static ring, spacer ring, stud bolts, flocculation mixer, electrical control box, and more. In this article, we will discuss the working principle and benefits of using a sludge dewatering system.

To begin with, one needs a dosing machine, which is merely a mixer. The raw materials and medicines have to be mixed to produce precipitation. Then, it is pumped into the barrel of the separator, stirred, and finally pumped into the separator to separate the sludge and water. The machine adopts the integrated form of a screw shaft, concentration section, and dehydration section. [ Read also: Screw Press Sludge Dewatering ]

When the screw push shaft rotates, the multiple fixed and movable laminations located on the periphery of the push shaft move relatively. Under the action of gravity, the water is filtered out from the relatively moving lamination gap to achieve rapid concentration. The screen part is a cylindrical filter body formed by a fixed ring piece and a moving ring piece.

A filter body is formed by a cylinder formed by alternately overlapping fixed ring sheets and floating ring sheets, and a screw shaft runs through it. Solid-liquid separation is performed by forming pressure through the rotation of the screw shaft.

The gap between the screw shaft and the fixed ring and the moving ring gradually becomes smaller to form a dewatering section. The concentrated sludge moves forward with the rotation of the screw shaft. Along the outlet direction of the mud cake, the pitch of the screw shaft gradually becomes smaller, and the gap between the rings is also gradually reduced. The volume of the spiral cavity is constantly shrinking. Under the action of the back pressure plate at the outlet, the internal pressure gradually increases, and the water in the sludge is squeezed and discharged. Under the continuous operation of the screw shaft, the solid content of the filter cake continues to increase, and finally, the continuous dewatering of the sludge is realized.

The rotation of the screw shaft drives the moving ring to rotate continuously, and the equipment relies on the movement between the fixed ring and the moving ring to realize a continuous self-cleaning process. This cleverly avoids the common clogging problem of traditional dehydrators. At the same time, compared with the belt-type thickening dehydrator and the centrifugal dehydrator, the equipment cost and operating costs are reduced.

The sludge dewatering system has a compact design, small footprint, low energy consumption, low operating cost, high energy saving, high technology content, easy maintenance and replacement, low weight, and easy handling. It is especially suitable for small and medium-sized sewage plants, township sewage plants, and sewage treatment stations.

It can directly treat the sludge in the aeration tank and the secondary sedimentation tank, without the need to build a sludge thickening tank and a sludge storage tank, reducing the overall investment cost of infrastructure. This also avoids the problem of phosphorus release in the traditional sludge thickening tank, improving sewage treatment. The system dephosphorization function.

Using a sludge dewatering system helps save the cost of supporting equipment such as mixers and other structures. It also saves the cost of sludge dewatering equipment such as air compressors, flushing pumps, etc.

Furui Machinery Co.,Ltd is a top screw press dewatering machine manufacturer.

If you want to know more details, welcome to leave a message.

Call Us/WhatsApp

+86 193 3712 3736Email Us

inquiry03@furuimachinery.comOffice Address

No.78 Puhui RD, Jinshui District, Zhengzhou, China